Harbor Freight TIG welder foot pedal mod

-

PvtJoker

Harbor Freight TIG welder foot pedal mod

Just curious; would anyone here who has one of the Harbor Freight TIG welders be interested in how to add a foot pedal controller to it? I just got finished with this little side project, and while I haven't had a chance to try it out yet, I did take a bunch of photos if anyone would like to see how I did it. I figure I'll post this around a few forums.

Re: Harbor Freight TIG welder foot pedal mod

Just what I need....carry on, please

MikeD

MikeD

Re: Harbor Freight TIG welder foot pedal mod

Yes please set us know what you had to do!!!!!

Chuckm

Chuckm

Re: Harbor Freight TIG welder foot pedal mod

The big Tig welder I use has a foot pedal,and it makes all of the diferance.I would also like to see how you hooked up yours.It is like having an extra hand around when you need one! ---bil

"I dream of a world where I can buy alcohol,tobacco and firearms from the same drive-up window,and use them all on the way home from work!" Dogbert

- flemgunner

- Brigadegeneral

- Posts: 635

- Joined: Sat Apr 21, 2007 6:35 am

- Location: Texas

- Contact:

Re: Harbor Freight TIG welder foot pedal mod

Im interested in this as well

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

I've tried posting it a couple of times, but the photo size exceeded tags keep coming up. I'll have to resize all the photos before I can get it to work, so bear with me.

Re: Harbor Freight TIG welder foot pedal mod

Inthe mg42 photos section there is a good free resizer program if you need one.I use it all the time.I just need to learn to set the camera.Maybe I need a smaller camera. ---bil

"I dream of a world where I can buy alcohol,tobacco and firearms from the same drive-up window,and use them all on the way home from work!" Dogbert

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

I've got them already loaded up on photobucket, and tried batch resizing them there, but it only lets me do one at a time and there is a crapload of them to do. Add to that the fact that my computer is powered by a hamster on treadmill (with a broken leg at that) and it just takes a while... But it WILL get done and posted.

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

Alrighty, then.  What I started with was a new-in-the-box HF TIG welder, and for the foot pedal, I used a Casio volume foot-controller that I got off eBay for about $30. The model number for it is VP-2.

What I started with was a new-in-the-box HF TIG welder, and for the foot pedal, I used a Casio volume foot-controller that I got off eBay for about $30. The model number for it is VP-2.

Start out by pulling the control knob off the TIG welder, and use a 10mm box wrench to remove it from the panel.

Then remove the cover from the welder AFTER MAKING SURE IT IS UNPLUGGED AND DISCHARGED (do NOT get yourself zapped!)

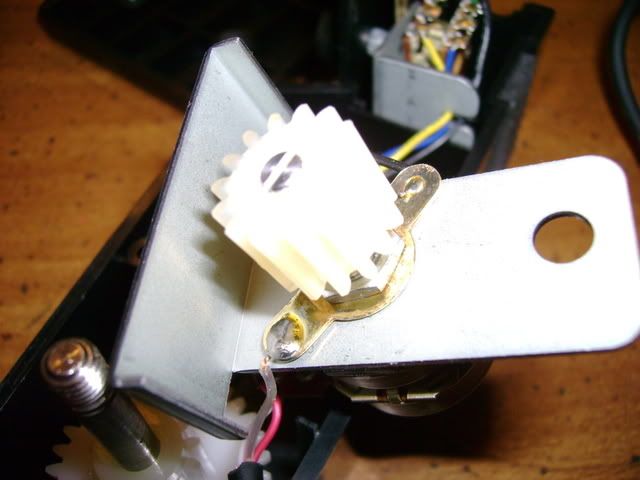

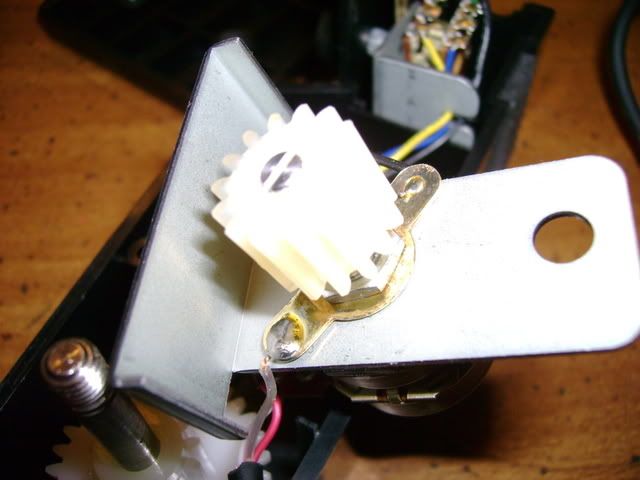

Here's the backside of the adjuster, that is pulled from the rear. It is attached to a small circuit board and that connects to the wiring to the welder. I did not try to detach the small white plug from the board, as it seemed fragile and might be hard to find a matching replacement.

Notice the spec on the pot. This is different than the one on the pedal, so it would not work as a direct plug-in. But there IS a solution...

Here's the foot controller out of the box.

The knob on top of it gets eliminated in the conversion.

As does the plug.

Start the disassembly of the pedal by removing the screw on the side.

Once that's off, here's what the guts look like.

Another side view of how it goes together.

Here's the pot that is attached to the pedal. It has a double set-up that uses the knob on top as a limit, with the pedal travel going inbetween the limits. This mod will eliminate that, as I didn't want to add too many variables to the control circuit load for the welder.

Notice that the pedal pot is a different value. The way I solved this was to adapt the original welder's pot in place of the ones in the pedal.

This one on the pedal also goes away.

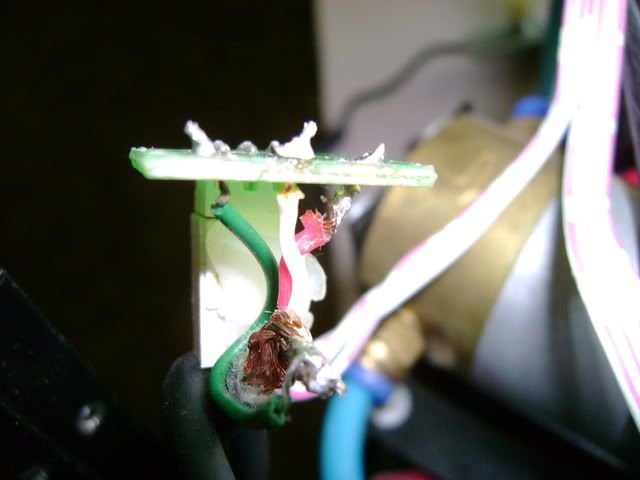

Using a soldering iron, carefully heat the wires where attached just enough to remove the cable's three connections from the pedal's pot, and then do the same to where they are soldered to the plug.

Remove the circlip that holds the pot bracket and gears, and pay attention to the order and direction that the parts all fit so you don't put any of them on backwards the first time (ask me how I know this- D'OAH!).

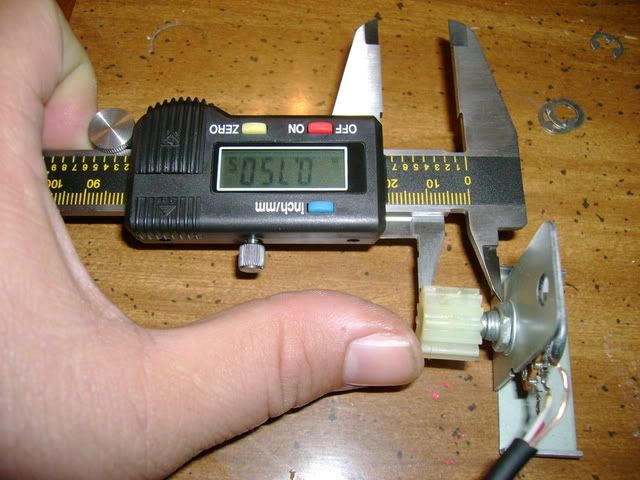

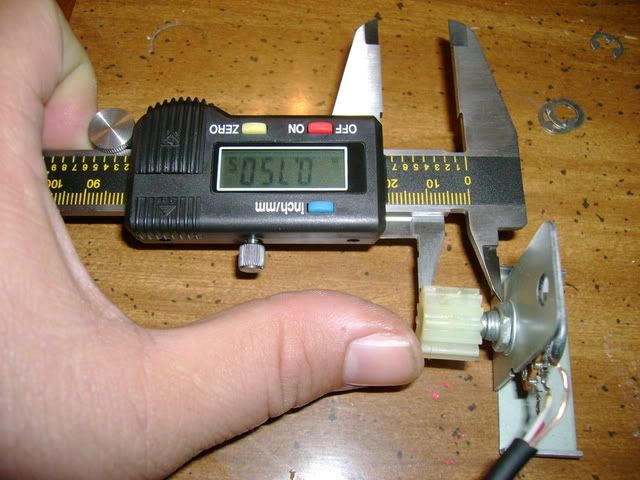

Notice that the gear extends .75 inch from its outer edge to the bracket on the original pot. This measurement needs to be matched when you slip it over the welder's pot. It fits the shaft OK, but the shaft is shorter so be sure to measure it to make the gears line up correctly. (and yes, the pot IS on the bracket backwards in the photo)

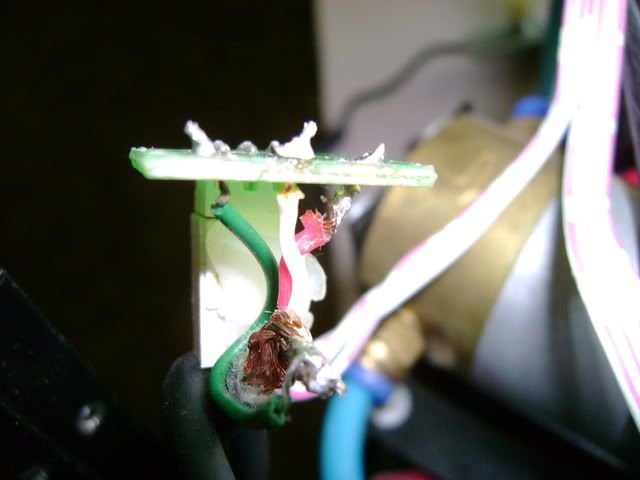

Now, you can use the pedal's cable to save money. The welder's pot has three terminals, as does the small circuit board. BE SURE TO MATCH THE COLORS ON EACH END OF THE WIRE TO WHICHEVER CORRESPONDING TERMINAL WENT FROM THE POT TO THE BOARD. Which wire you use isn't as important as is being sure that they are not crossed from how the pot originally attached. For the part of the cable that uses a wire sheath, I salvaged one of the short wires from the pedal pot connections, to fit up in the board. Be sure to remember to run the wire through the hole in the panel BEFORE you attach it to the circuit board, and to put a small loose loop in the cable to help keep it from pulling out or stressing the solder points in the board.

I kept the plug housing and spring on it to give it a little extra support, but you could just as well simply use a little silicone or rubber grommet where the cable goes into the panel.

Now that the cable is wired in, you need to install it in the pedal bracket. Use the 10mm wrench to gently tighten it with the wires positioned to give clearance in the pedal housing. Be sure when you are putting it back together to notice the notch on the main shaft that the gear rotates on, and get it back in the proper slot to fit. Also be sure to set the pedal in the right position, by noting which direction the original pot is turned to give its lowest number. Then install the bracket with the pot, and put the pedal in, aligning the gear on the pedal to the main gear with the pedal fully up and the pot on low. Gently check its travel and if it operates cleanly, proceed to route the wire through the hole on the front of the pedal housing, and be sure to reinstall the white plastic bushings the pedal rotates on, and the plate (with the original volume pot removed) on top of the pedal housing.

Put the housing back together, and there you go. That's as far as I've gotten with this myself yet. I haven't tested it yet, but I see no reason why it would not work, as it is still using the same controller pot as before, just relocated to a foot pedal.

Hopefully, it will work and will make it easier to control the temp when TIG welding. The pedal stays where you leave it, so your foot shouldn't have to be on it constantly, but if you need to vary the temp it would be FAR easier with both hands free to hold the torch and the rod, and to not have to look away in the middle of a weld. Many thanks to Pirate for his TIG tutorial that got me to buy one of these harbor freight TIGs in the first place, and to Col Krenk over on the AK Files for his suggestion of what foot pedal to use. Thanks, y'all, and maybe this will help some of you guys like so many others have contributed to my knowledge base along the way.

Start out by pulling the control knob off the TIG welder, and use a 10mm box wrench to remove it from the panel.

Then remove the cover from the welder AFTER MAKING SURE IT IS UNPLUGGED AND DISCHARGED (do NOT get yourself zapped!)

Here's the backside of the adjuster, that is pulled from the rear. It is attached to a small circuit board and that connects to the wiring to the welder. I did not try to detach the small white plug from the board, as it seemed fragile and might be hard to find a matching replacement.

Notice the spec on the pot. This is different than the one on the pedal, so it would not work as a direct plug-in. But there IS a solution...

Here's the foot controller out of the box.

The knob on top of it gets eliminated in the conversion.

As does the plug.

Start the disassembly of the pedal by removing the screw on the side.

Once that's off, here's what the guts look like.

Another side view of how it goes together.

Here's the pot that is attached to the pedal. It has a double set-up that uses the knob on top as a limit, with the pedal travel going inbetween the limits. This mod will eliminate that, as I didn't want to add too many variables to the control circuit load for the welder.

Notice that the pedal pot is a different value. The way I solved this was to adapt the original welder's pot in place of the ones in the pedal.

This one on the pedal also goes away.

Using a soldering iron, carefully heat the wires where attached just enough to remove the cable's three connections from the pedal's pot, and then do the same to where they are soldered to the plug.

Remove the circlip that holds the pot bracket and gears, and pay attention to the order and direction that the parts all fit so you don't put any of them on backwards the first time (ask me how I know this- D'OAH!).

Notice that the gear extends .75 inch from its outer edge to the bracket on the original pot. This measurement needs to be matched when you slip it over the welder's pot. It fits the shaft OK, but the shaft is shorter so be sure to measure it to make the gears line up correctly. (and yes, the pot IS on the bracket backwards in the photo)

Now, you can use the pedal's cable to save money. The welder's pot has three terminals, as does the small circuit board. BE SURE TO MATCH THE COLORS ON EACH END OF THE WIRE TO WHICHEVER CORRESPONDING TERMINAL WENT FROM THE POT TO THE BOARD. Which wire you use isn't as important as is being sure that they are not crossed from how the pot originally attached. For the part of the cable that uses a wire sheath, I salvaged one of the short wires from the pedal pot connections, to fit up in the board. Be sure to remember to run the wire through the hole in the panel BEFORE you attach it to the circuit board, and to put a small loose loop in the cable to help keep it from pulling out or stressing the solder points in the board.

I kept the plug housing and spring on it to give it a little extra support, but you could just as well simply use a little silicone or rubber grommet where the cable goes into the panel.

Now that the cable is wired in, you need to install it in the pedal bracket. Use the 10mm wrench to gently tighten it with the wires positioned to give clearance in the pedal housing. Be sure when you are putting it back together to notice the notch on the main shaft that the gear rotates on, and get it back in the proper slot to fit. Also be sure to set the pedal in the right position, by noting which direction the original pot is turned to give its lowest number. Then install the bracket with the pot, and put the pedal in, aligning the gear on the pedal to the main gear with the pedal fully up and the pot on low. Gently check its travel and if it operates cleanly, proceed to route the wire through the hole on the front of the pedal housing, and be sure to reinstall the white plastic bushings the pedal rotates on, and the plate (with the original volume pot removed) on top of the pedal housing.

Put the housing back together, and there you go. That's as far as I've gotten with this myself yet. I haven't tested it yet, but I see no reason why it would not work, as it is still using the same controller pot as before, just relocated to a foot pedal.

Hopefully, it will work and will make it easier to control the temp when TIG welding. The pedal stays where you leave it, so your foot shouldn't have to be on it constantly, but if you need to vary the temp it would be FAR easier with both hands free to hold the torch and the rod, and to not have to look away in the middle of a weld. Many thanks to Pirate for his TIG tutorial that got me to buy one of these harbor freight TIGs in the first place, and to Col Krenk over on the AK Files for his suggestion of what foot pedal to use. Thanks, y'all, and maybe this will help some of you guys like so many others have contributed to my knowledge base along the way.

Re: Harbor Freight TIG welder foot pedal mod

This should be a stickie-if I knew how,I would do it,the last post I tried went away!  Very nice tutorial ---bil

Very nice tutorial ---bil

"I dream of a world where I can buy alcohol,tobacco and firearms from the same drive-up window,and use them all on the way home from work!" Dogbert

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

Thanks, Bil. If it gets lost, I can repost it.

-

Jason222

Re: Harbor Freight TIG welder foot pedal mod

Id like a mod to make my HF MIG turn on and of with a foot pedal to eliminate the always hot tip. This is a good idea starter

-

TbcSEOD

Re: Harbor Freight TIG welder foot pedal mod

Its such a simple idea, and yet I have never thought of it or seen it before!

I will be getting right on this mod as welding up thin receiver metal is not always easy with a constant tip setting!

Thank you again!

~TbcSEOD

I will be getting right on this mod as welding up thin receiver metal is not always easy with a constant tip setting!

Thank you again!

~TbcSEOD

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

OK; I FINALLY got a chance to try out my pedal modified TIG welder this afternoon, so I thought I'd post an update.

All in all, it did work, although I got mixed results. Thing was, I was trying a couple of ideas at once, and not all of it went according to plan. I tried using a magnesium strip held onto the metal by a strong little cube magnet, based on a conversation with a more experienced welder on another forum who said that the tungsten tip would not stick to it. So, I figured use it as a scratch start pad, and then go over to the steel once I had an arc. Unfortunantly, once it struck, it burned a hole straight through the magnesium, and even toasted the little magnet good.on one side. So that one managed to snatch defeat from the jaws of victory, and fouled up the tip in the process. That said, though, it DID change power via the pedal, so I guess THAT part of it works. Sure weren't very pretty results, but I guess every new thing takes a little time to master. Of course, the fact that I was the one doing the welding had FAR more effect on the results than the mod itself. Somewhere there's a graphic for a monkey humping a football, but I'm too tired to search for it right now...

So that one managed to snatch defeat from the jaws of victory, and fouled up the tip in the process. That said, though, it DID change power via the pedal, so I guess THAT part of it works. Sure weren't very pretty results, but I guess every new thing takes a little time to master. Of course, the fact that I was the one doing the welding had FAR more effect on the results than the mod itself. Somewhere there's a graphic for a monkey humping a football, but I'm too tired to search for it right now...

Oh well, back to the lab, Pinky!!!

All in all, it did work, although I got mixed results. Thing was, I was trying a couple of ideas at once, and not all of it went according to plan. I tried using a magnesium strip held onto the metal by a strong little cube magnet, based on a conversation with a more experienced welder on another forum who said that the tungsten tip would not stick to it. So, I figured use it as a scratch start pad, and then go over to the steel once I had an arc. Unfortunantly, once it struck, it burned a hole straight through the magnesium, and even toasted the little magnet good.on one side.

Oh well, back to the lab, Pinky!!!

- flemgunner

- Brigadegeneral

- Posts: 635

- Joined: Sat Apr 21, 2007 6:35 am

- Location: Texas

- Contact:

Re: Harbor Freight TIG welder foot pedal mod

Yeah I tried to scratch off a penny once. Melted the hell out of it.

Re: Harbor Freight TIG welder foot pedal mod

I saw an old sewing machine today and got to thinking-would the foot pedal for one of those work? Not the kind you pedal  ,but the newer type. ---bil

,but the newer type. ---bil

"I dream of a world where I can buy alcohol,tobacco and firearms from the same drive-up window,and use them all on the way home from work!" Dogbert

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

I don't know how those are made, Bil, so I really can't say if it could or couldn't be made to work. What's it look like on the inside of the pedal?

-

cowboy255

Re: Harbor Freight TIG welder foot pedal mod

Check out this PDF "How on TIG welding" posted by JBaum a few posts below. hete it is just in case. Very informative.

http://mg42.us/viewtopic.php?f=10&t=7476

http://mg42.us/viewtopic.php?f=10&t=7476

-

DougF

Re: Harbor Freight TIG welder foot pedal mod

I don't have one of these little TIG welders because Harbor Freight has stopped selling them. However, I have been researching them and in the process, I ran across an interesting post in this forum:flemgunner wrote:Yeah I tried to scratch off a penny once. Melted the hell out of it.

http://www.practicalmachinist.com/vb/sh ... p?p=805672

The individual posting the message says that this welder has a "lift" start rather than a "scratch" start. Below is a copy of the pertinent parts of his post.

"...Regarding the 91811, I have one, and I like it. I also have a "real" tig welder, a monster vintage Lincoln Idealarc Tig 300/300, so I'm impressed how well this little HF unit actually works.

When tigging, the unit is actually lift start, not scratch start, which is much easier. It took me awhile to figure this out (it was not mentioned in the crappy instructions), up to that point it was really frustrating me. I got this box cheap, the former owner was also frustrated with it and gave up on it. I almost did too, but after realizing it was lift start, the difference was like night & day. When you touch and hold the electrode against the work, the gas starts; the arc starts when you lift..." I think this was post #5. Hope this helps someone.

-

PvtJoker

Re: Harbor Freight TIG welder foot pedal mod

Interesting... I'll have to give that a try; thanks!